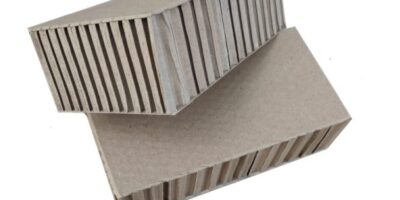

HONEYCOMB PAPER PLATE

The inspiration for the honeycomb structure in industry is nature. Commonly known is bee honeycomb, but this structure also occurs naturally in bones, rocks, plant stems or tree trunks.

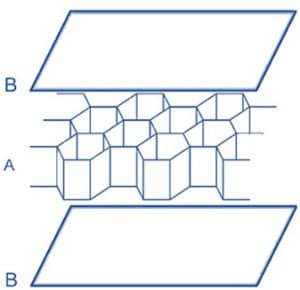

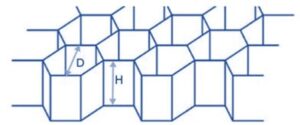

In industry, a honeycomb structure is made of a wide range of materials, including plastics, aluminum, steel or paper. Not only the structure itself affects the strength of the panel, the material is also important, but the cell size (i.e. the size of a circle inscribed in a given hexagon) in the case of honeycomb core is crucial. Thanks to nature, man was able to copy a structure that allows minimizing the consumption of building material, reducing weight, while maintaining very high strength of the finished product. It is used on a large scale not only in packaging, but also in e.g. in building, aircraft and spacecraft structures.

The history of honeycomb structures used by man goes back 2000 years, when the Chinese used them as ornaments. However, the amazing properties of this structure were implemented on a large scale thanks to Mr. Hans Heilbrun in 1901 in Halle (Germany), who was the first to start producing a paper core with a honeycomb structure.

The first use of honeycomb in industry was in 1915. It was used by Hugo Junkers, who owned a German aerospace company.

APPLICATION OF PAPER BOARDS WITH HONEYCOMB STRUCTURE

Thanks to legislative changes and consumer needs, based on concern for the future of our planet, the demand for paper products is constantly growing. To a large extent, this is influenced by changes in product packaging, reducing their weight and changes aimed at excluding plastics from packaging (replacing polystyrene EPS, plastic, foil). Implementation of changes in many industries has been taking place for a long time, but the ever-increasing pressure from governments from year to year indirectly causes a significant increase in demand for honeycomb products in many industries.

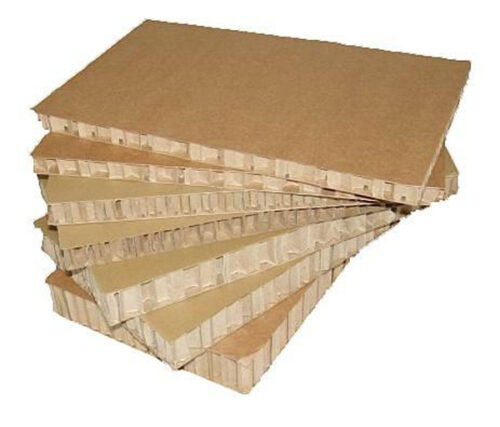

Honeycomb board has many names, it is a relatively new product and the terminology has not yet become standardized in common use. It is called e.g. honeycomb board, honeycomb paper board, paper honeycomb plates or honeycomb fillers. Paper honeycomb boards have many advantages that make them the obvious choice among packaging designers. They are characterized by, among others:

- high strength and stiffness in relation to the weight,

- high compressive strength at low weight,

- easy to process and manipulate,

- 100% recyclable.

The honeycomb fillers, compared to corrugated or solid cardboard materials, is characterized by high material savings (in our case paper and glue), thanks to the unique structure of hexagons, which results in the displacement of aluminum and plastic materials (e.g. polystyrene).