Many production and distribution companies are currently wondering what to replace polystyrene in the packaging of their products. Currently looking for polystyrene substitutes with similar properties (weight, strength, …). Replacing polystyrene in packaging with alternative solutions is caused not only by the growing concern for the environment of consumers, but also by introducing ecological solutions allows for measurable financial benefits in the company.

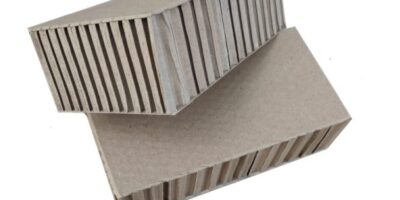

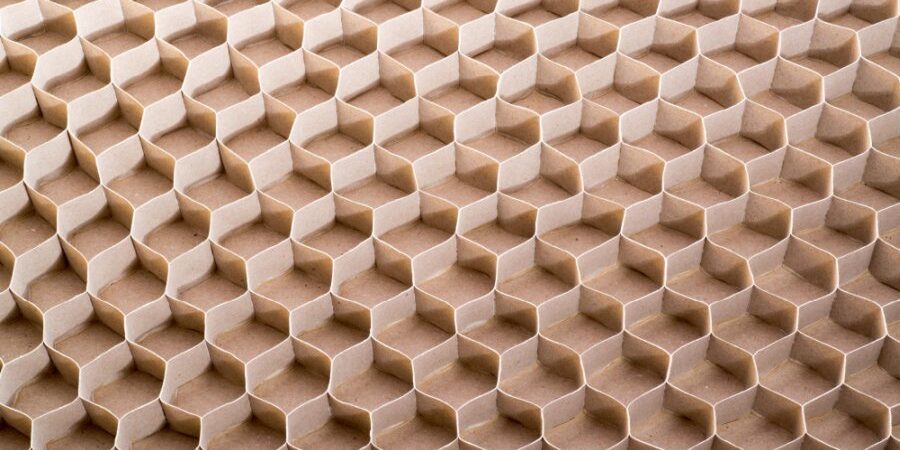

We produce paper honeycomb fillers and protections from very large (5×2.1 m) to smaller ones (1×2 cm). The honeycomb board is characterized by high resistance to compression, it can protect even multi-ton loads in transport. It is a universal product, thanks to many processing methods, we can prepare the board in the form necessary to protect the product. Paper is not difficult for the final recipient, unlike polystyrene, our honeycomb boards do not crumble, and getting rid of the waste is simple: throw the board into a container intended for paper.

In transport to the customer, the plate can protect the top, bottom, walls and corners of the product. Thanks to various forms, the paper honeycomb plate can be hung over the product, glued to it (or, for example, to foil), loosely placed in a package or cut to the shape of the product, protecting it. Honeycomb boards of various shapes are the simplest solution when a company wants to replace polystyrene. Thanks to the wide range of honeycomb cell sizes, which significantly affects strength, the optimal solution should be selected. Since standard panels have a strength of up to 50 t/sqm, a solution should be chosen that will minimize the company’s costs by choosing a solution with appropriate strength (5-30 t/sqm is most often used).

We have placed some of our projects on the website: GALLERY.

In production, we use 100% recycled paper.

Thanks to many years of experience, we support you during these positive changes! Feel free to contact us.